Blown Film Extruder Machine for PVC Shrink Film Label Grade Film

More video check here !

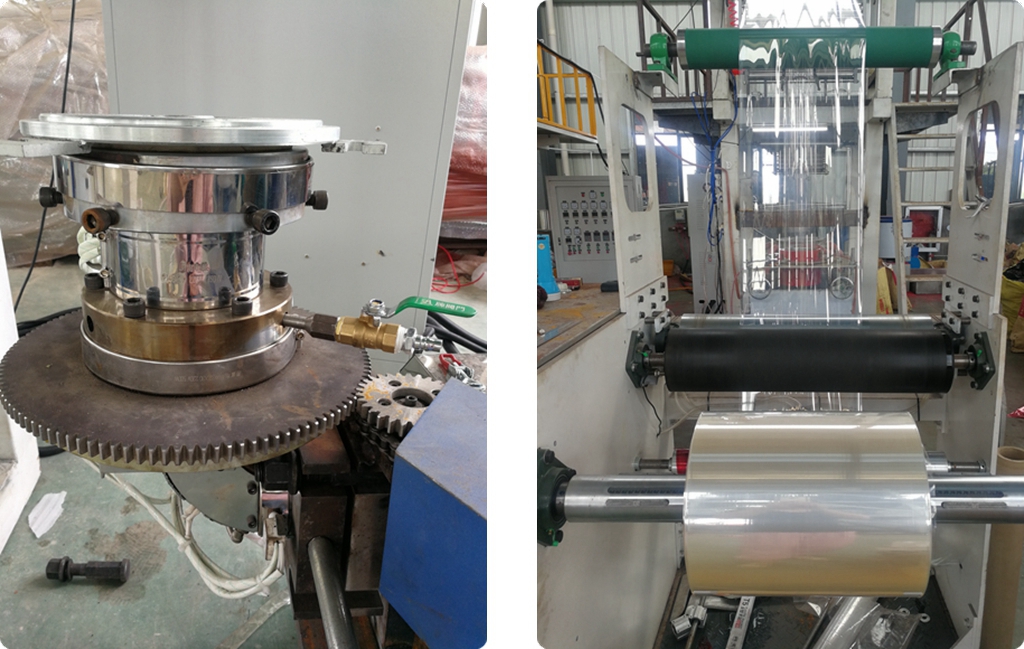

Sample Pictures:

Range of application:

It is widely used in food, beverage, tea, glass products, handicraft, sanitary ware and cosmetics. Outerwear of products, electronic products, etc.

Introduction:

This machine is suitable for blowing film of various specifications by tube film process of PVC plastic resin. The film has the advantages of good transparency, good gloss and high shrinkage. It is a new popular packaging material nowadays.

Main Features:

1. The unit is mainly composed of plastic extruder, air ring, nose device, traction device, cooling device, heating expansion device, winding device, heating system and electronic control device.

2. The key parts of screw and barrel are made of 38GrMoAIA high-quality alloy steel, which has high hardness, wear resistance and corrosion resistance after finishing and ammonization treatment.

3. The new screw with a length of 1:28 is suitable for mixing and plasticizing polyvinyl chloride (PVC) plastics with high melt viscosity and poor thermal stability.

4. The automatic temperature control system is equipped to control the heaters and cooling fans of the fuselage so as to keep the temperature constant, accurate and in line with the technological requirements of film production and ensure the excellent quality of the heat recovery film.

5. The special structure of die head and air ring is favorable for plasticizing and cooling requirements.

6. Easy to operate, compact structure, centralized control and high degree of automation.

Details: customized is available

blown film extruder machine, blowing film extruder machine, film blowing machine, extrusion blow molding machine, plastic film blowing machine, shrink film, shrink label, beverage label film, bottle label, pvc shrink label,

Main Technical Parameters:

The whole machine is divided into four parts: main machine part, traction device, temperature control box and Rewinding part. The details are as follows:

| Model | SJ-75/1400 |

| Suitable Material |

PVC |

| Film Width(mm) | 800-1200 |

| Film Thickness(mm) | 0.02-0.1 |

| Max Extrusion Output HD | 70-120kg/hr |

| Gear Box | Hardened Gearbox (Chinese National Standard) |

| Screw Diameter(mm) | Φ75 |

| Screw ratio L/D | 1:28 Hard chrome plating |

| Die head | Φ180, up-rotation, rotary mold is optional |

| Air Ring | High-pressure air inlet |

| Barrel’s Cooling Fan | 250W*3 |

| Thermo Control (zone) | 8 |

| Driving Motor (kw) | 45 |

| Cooling mode | Water control |

| Hot Water Tank | Stainless steel, power 3kw*6 |

| Thermocouple | Stainless steel, extends into the interior of the hot water tank |

| Take-Up Motor (kw) | 3.7 |

| Type of Winder | Single winder, dual winder is optional |

| Roller Width (mm) | 1400 |

| Winding Power (kw) | 15 kg/Nm |

| Winding Speed(M/min) | 5-40m/min |

| Voltage | 380V/50HZ/3PHASE |

| Cover Dimension(mm) | 6500*2500*4000mm |

Please note: mentor company is continuously seeking for development of products. For this reason, mentor reserves the right to supply the improved product without advance notice.

Optional (need extra cost):

Production Process:

pvc shrink film blowing machine → printing machine → shrink sleeve seaming machine → sheet cutting machine (if need) → recycling machine

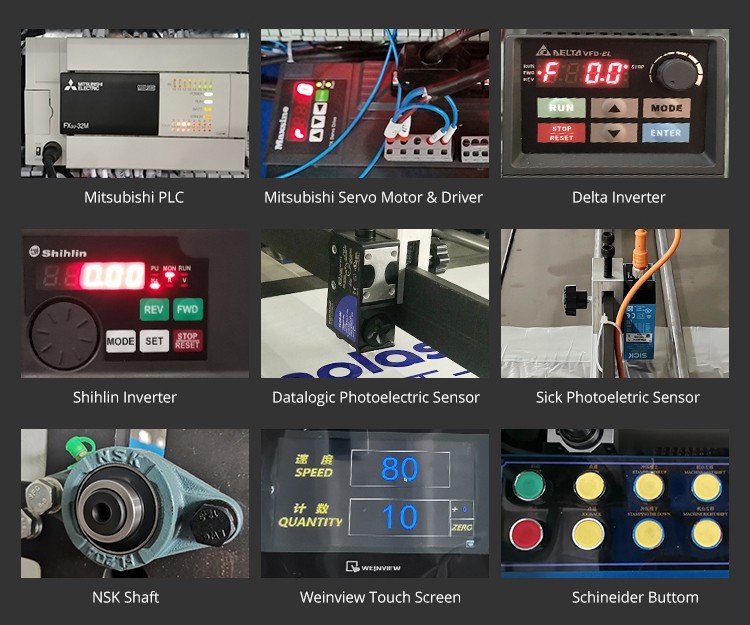

Brand we work with:

Package and Delivery:

What Does the Customer Say:

FAQ:

Q: What’s the price of machines?

A: Pls provide following information:

1) What is your material? Hdpe ldpe or PP?

2) What’s the maximum and minimum width of film?

3) What’s the thickness?

4) You also can let us know the screw dia. As like 45 50 55 60 65 etc.